Redefining The Current

As Australia marches towards an ambitious 2050 net-zero emissions target, GMG plans to use its revolutionary nanomaterial to solve two key energy hurdles: air conditioning and battery technology. The company, unsurprisingly, intends to take its solutions to the world, after proving them here.

“Around 25 per cent of Australia’s electricity is used for air conditioning,” says Craig, explaining that the nation’s power grids are built to handle a few scorching days a year – when every house, building and business is running an air conditioner.

By painting the coils of an air conditioner with their graphene-infused coating, GMG can dramatically improve heat transfer. The graphene shifts heat via phonons, through tiny quantum-level vibrations, allowing condensers to shed heat faster, work less, and switch off sooner. The result, Craig explains, is a staggering 20-30 per cent reduction in energy use.

“It basically removes the heat faster and then switches off the fan and the compressor,” says Craig, before showing us that the coating also prevents corrosion. He points to a series of containers, each with a submerged condenser, showing that the non-treated examples are corroded, while the graphene-coated sample is as new. Again, the benefits of graphene feel endless.

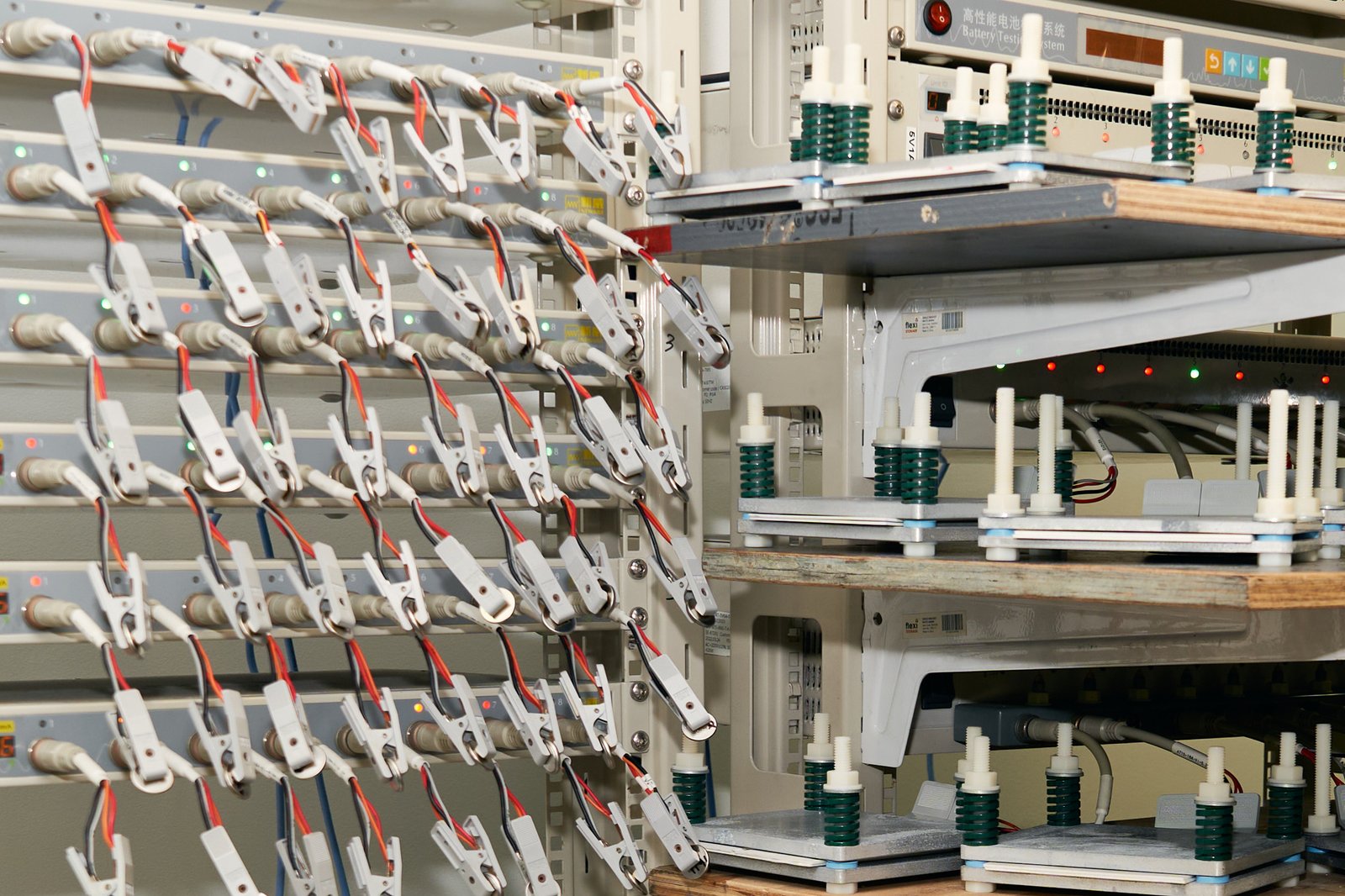

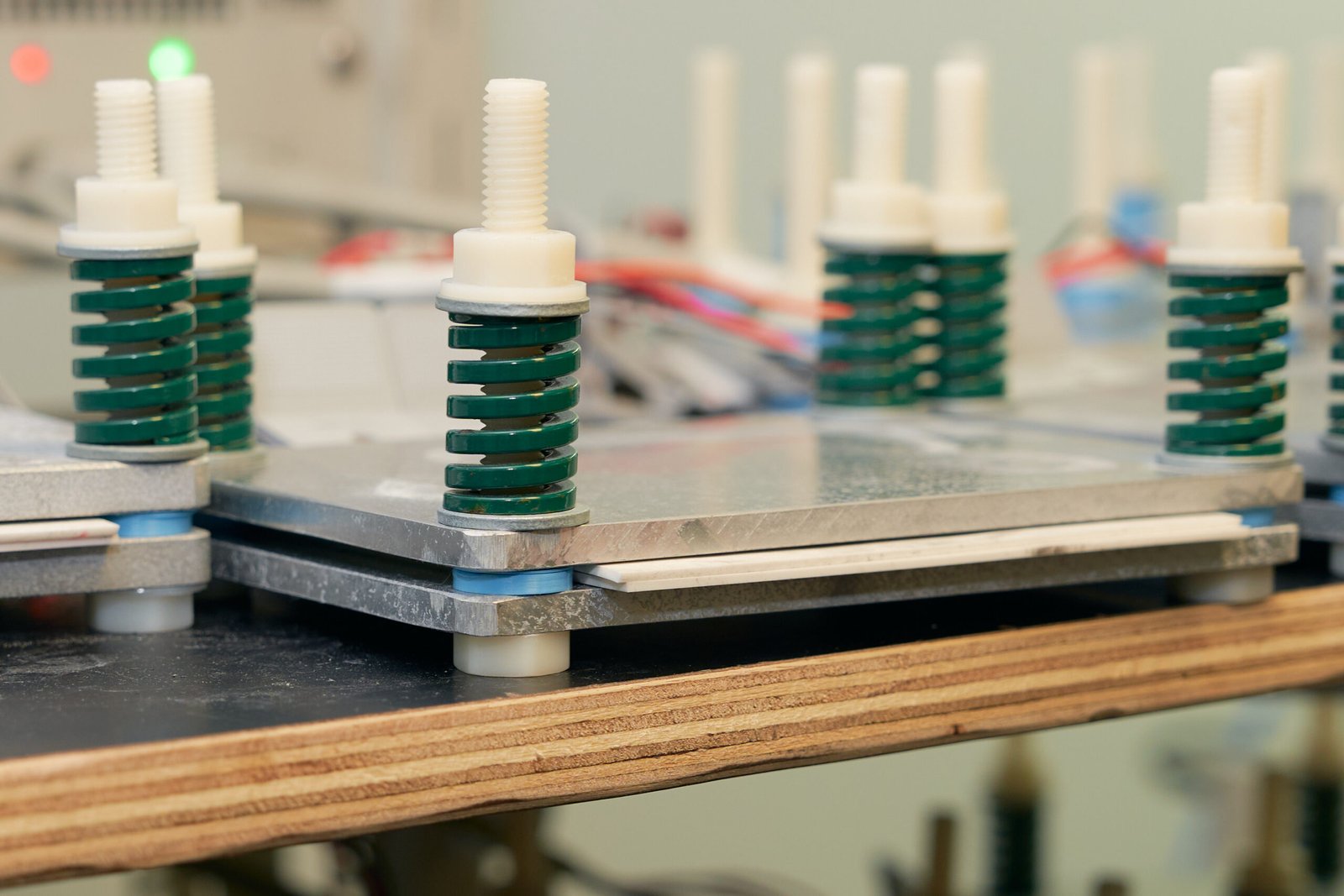

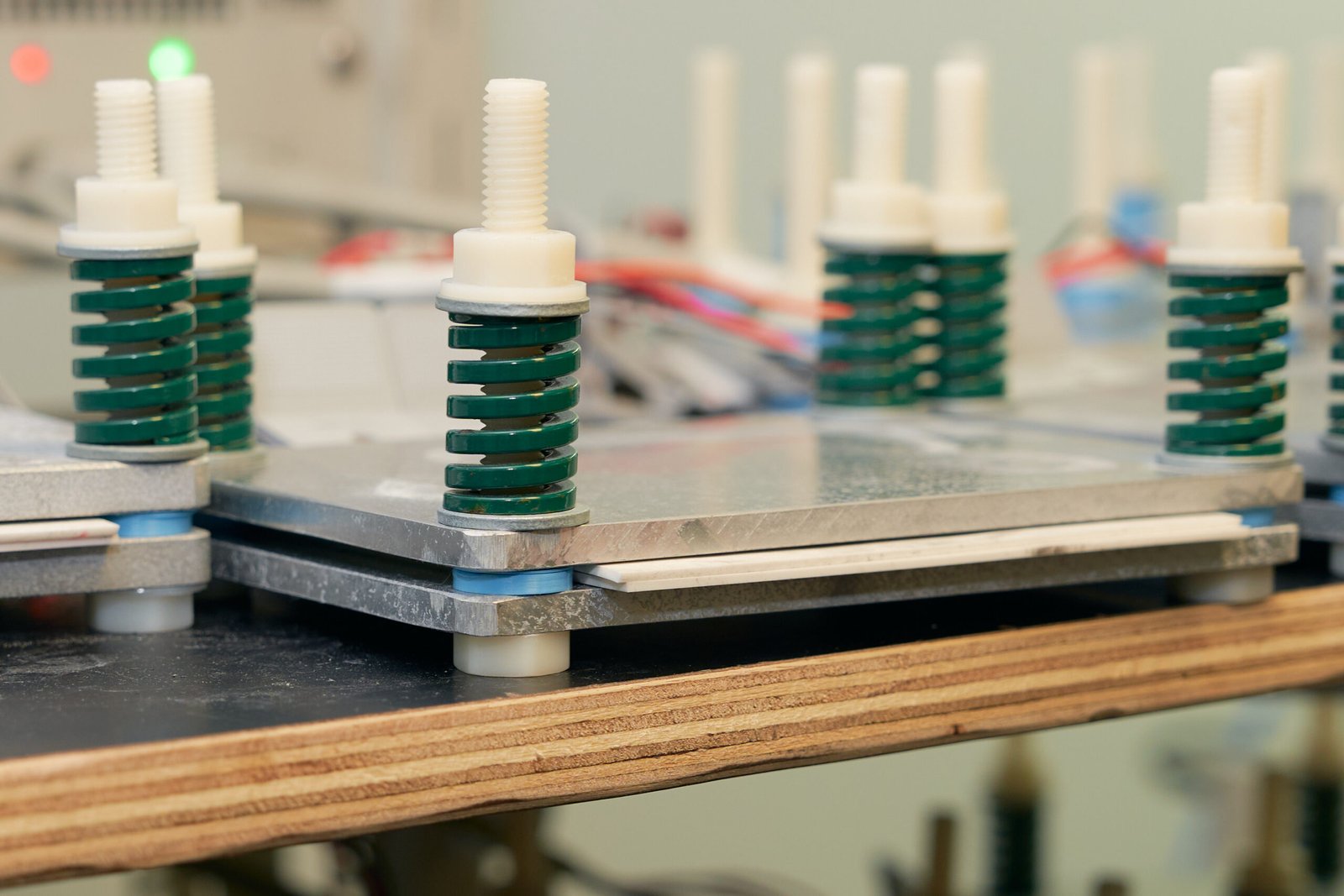

Even more transformative is GMG’s work in energy storage. The company is developing a Graphene Aluminium-Ion Battery (GAIB), a technology that could revolutionise everything from personal electronics to electric vehicles and grid-scale storage. Developed in partnership with the University of Queensland, the battery uses GMG’s graphene on an aluminium foil cathode, a plain aluminium foil anode, and a liquid electrolyte. This chemistry alleviates the ethical and supply-chain issues of lithium-ion batteries, which rely on critical minerals like cobalt, lithium and or manganese. GMG’s battery uses no other critical minerals apart from abundant aluminium, and graphene made from natural gas.

The performance metrics are astounding, and Craig is quick to point out that he’s aware it sounds “too good to be true” to outsiders like us. GMG’s pouch cell prototypes can charge up to 60 times faster than the best lithium-ion cells. “If this was in your phone, you’d charge it in about 3 minutes,” he says, as we watch a technician place graphene on a sheet of aluminium. The batteries are also projected to have a lifespan up to five times longer and aren’t prone to the fire risks associated with lithium units.

This breakthrough has captured the attention of major players, including mining giant Rio Tinto, which is working with GMG to develop GAIBs for its fleet of mining trucks. For productivity-driven industries like mining, where a diesel truck takes minutes to refuel but an electric one can take hours to charge, ultra-fast-charging makes battery-electric vehicles tenable. “When you can charge that fast, the whole paradigm shifts,” Craig points out.

Clean Shift

As GMG stands at a tipping point, ready to partner with global players as it rolls out its technology, and there’s even talk of listing on an American-based Stock Exchange, the company’s mission remains grounded in a pragmatic vision for the future.

While the world demands headline-grabbing solutions, Craig believes the key to a sustainable transition lies in unglamorous, incremental gains. “Energy demand around efficiency is not sexy, right? But if we can all consume 10 per cent less fuel per year, the cost reduction and emissions outcome will be there,” he says “There’s a lot of talk about the fuel of choice, but the fuel of choice is the one you don’t burn.”

From doubling the strength of concrete to reducing the fire risk in buildings, the applications for GMG’s graphene appear limitless as Craig discusses the various successful trials he’s conducted. But, he remains laser-focused on where it can make the most meaningful impact: reducing energy consumption and building better batteries.

As we search for the next big solution in the race to decarbonise, the answer might lie in a single layer of carbon atoms.